ANALYSIS EXAMPLES

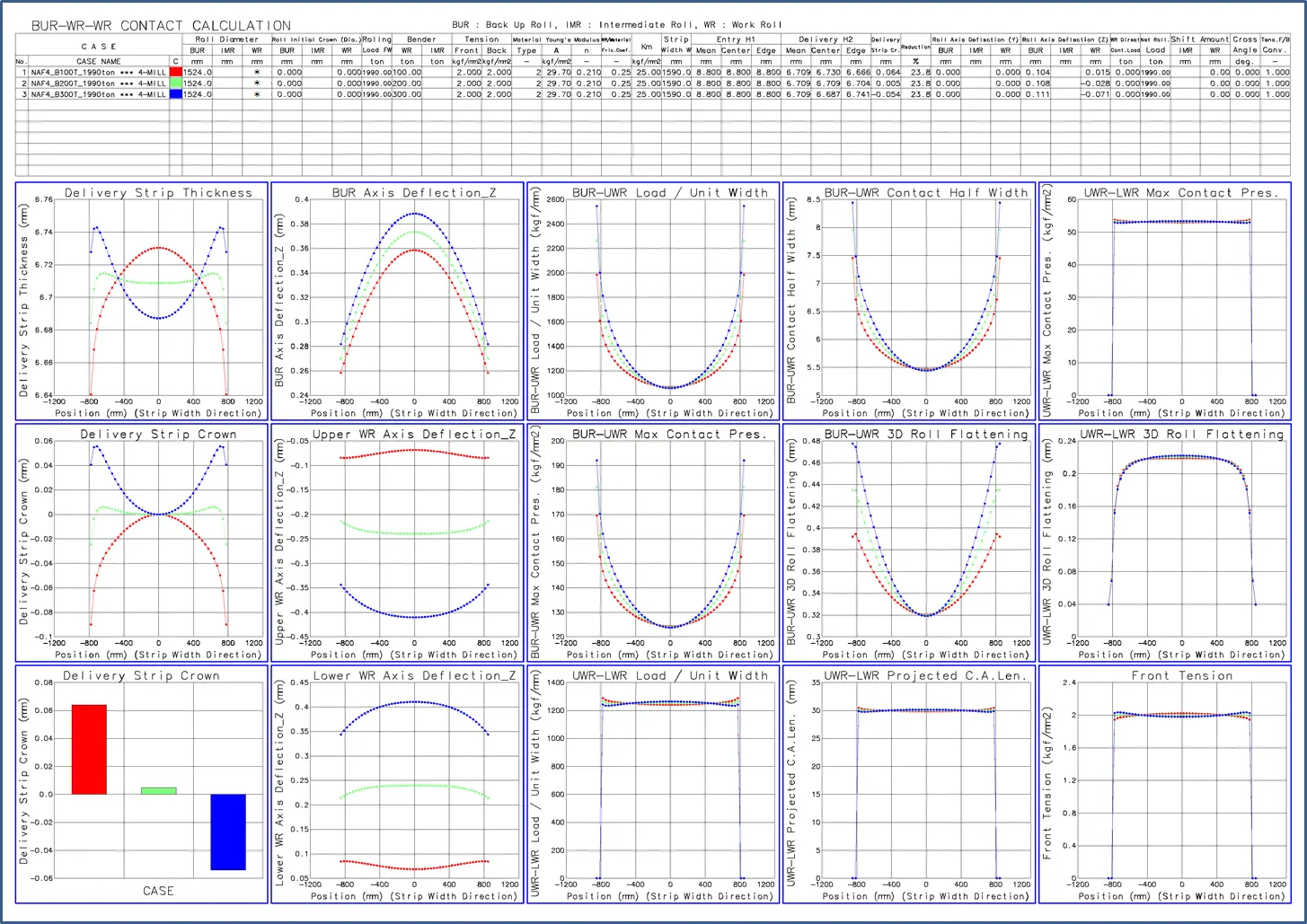

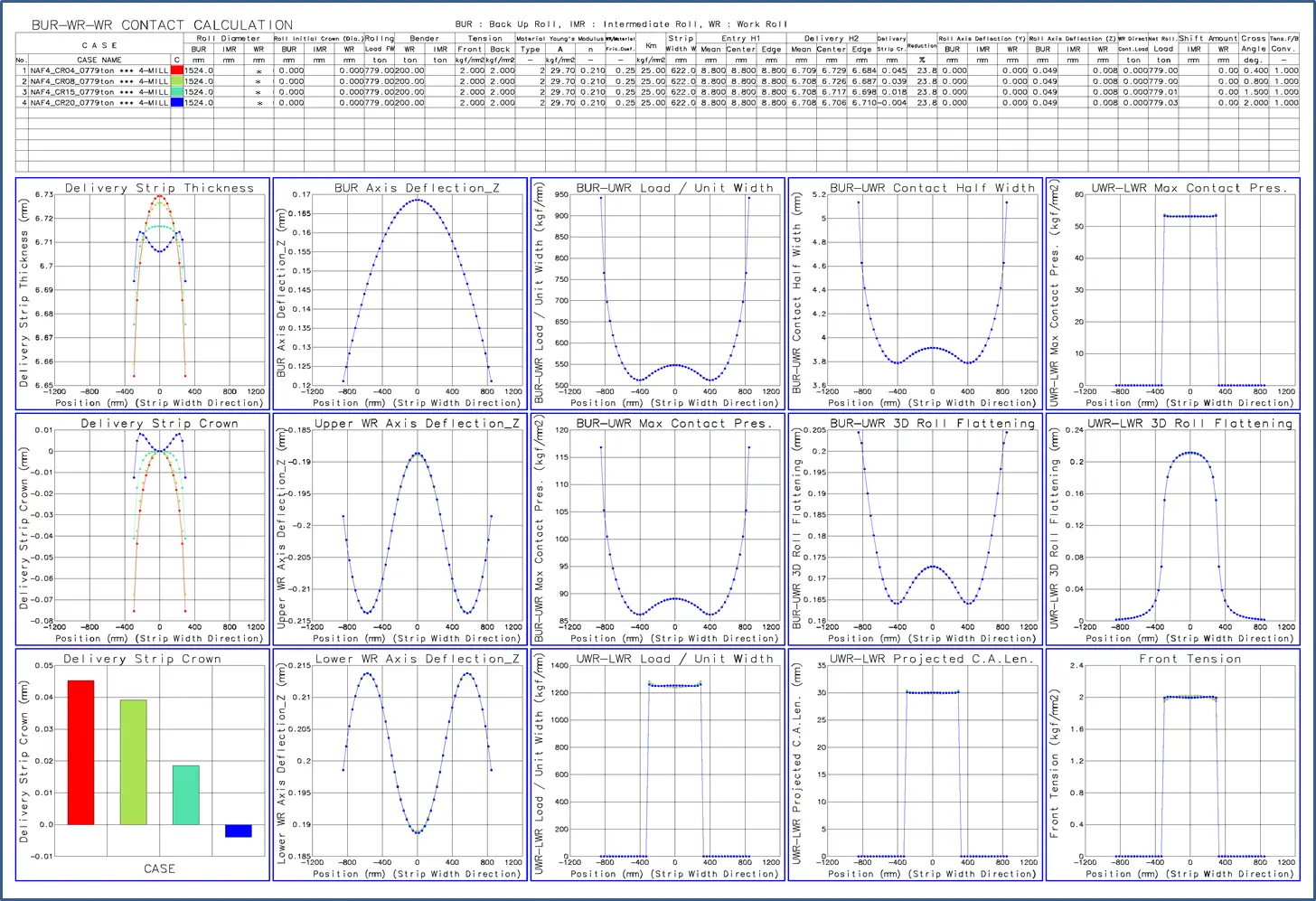

1. 4HI Mill(HOT)

FIG.1 Improvement of delivery strip crown with WR benders (Both WR benders、100、200,300 TON/2chocks) Strip width:622mm(narrow width)

FIG.2 Improvement of delivery strip crown (Both WR benders、100,200,300 TON/2chocks) Strip width:1590mm(wide width)

FIG.3 Improvement of delivery strip crown with WR benders( 200TON/2chocks const. )+ Pair cross rolling(All cross angle= 0.4°,0.8°,1.5°,2.0°) Strip width: 622mm(narrow width)

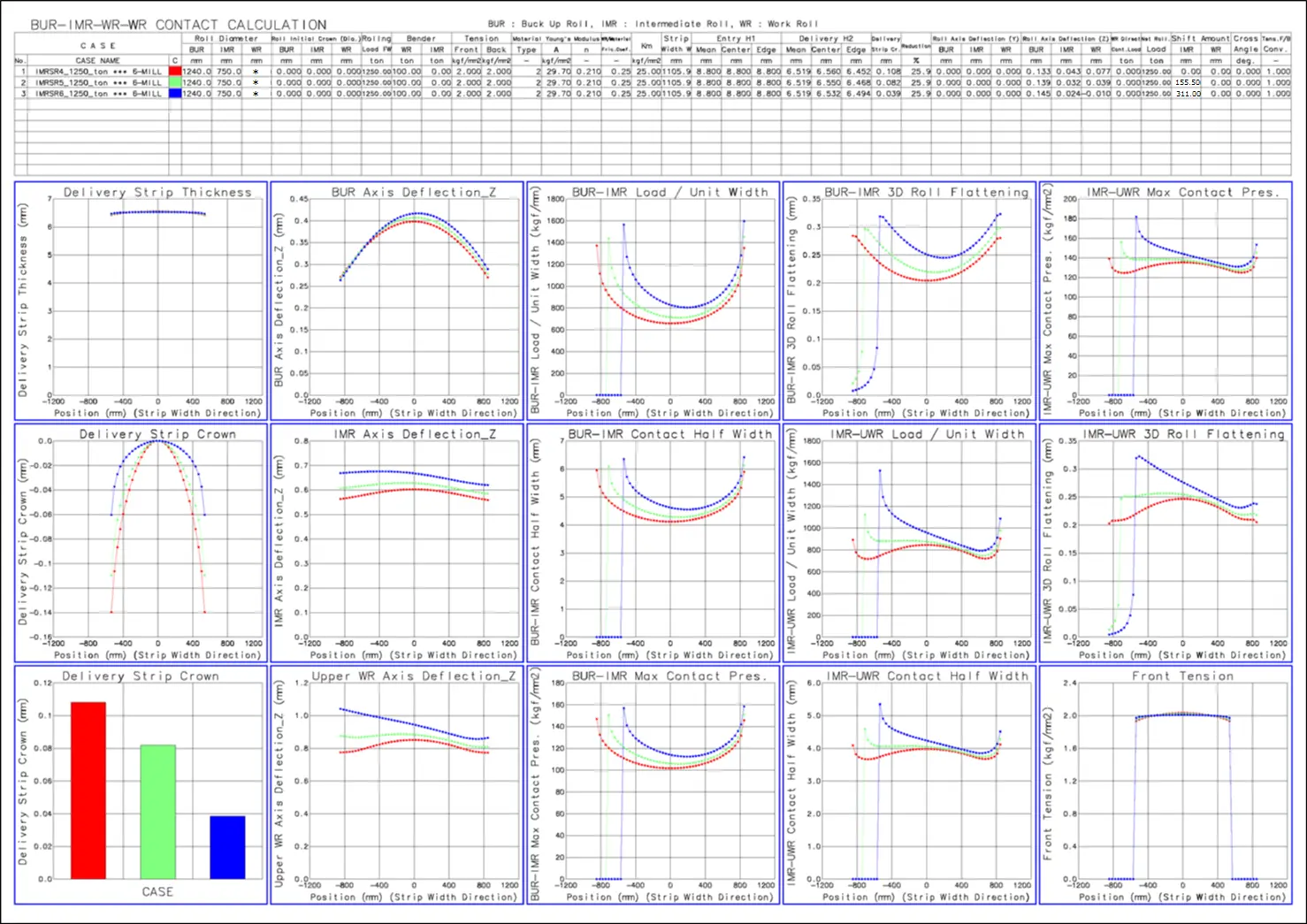

2. 6HI Mill(HOT)

FIG.4 Improvement of delivery strip crown with IMR shift amount and WR bender(IMR shift amount: 0, 155.5, 311 mm)、all WR benders=100 TON/2chocks,all IMR benders=0 TON/2chocks

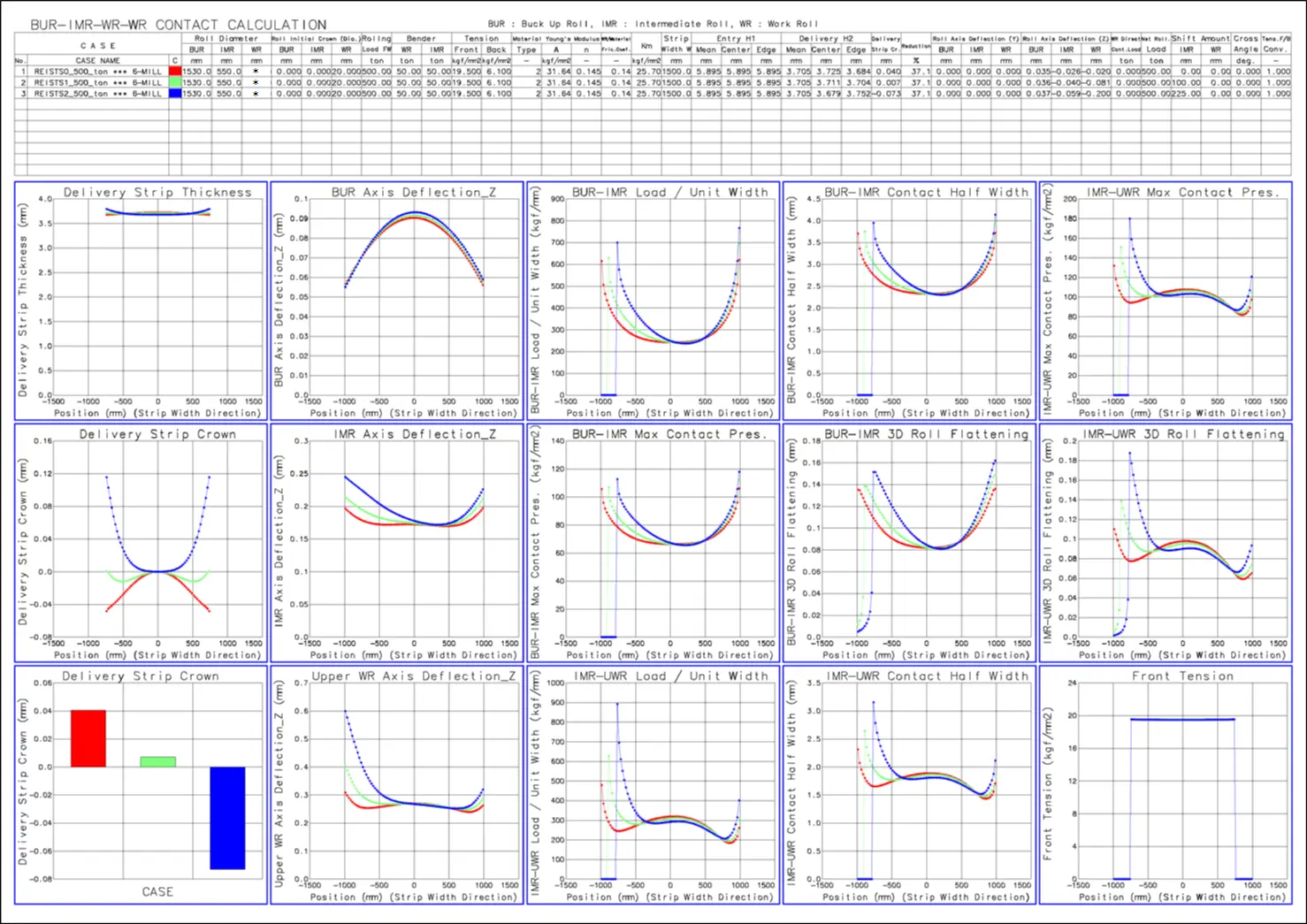

3. 6HI Mill(COLD)

FIG.5 Improvement of delivery strip crown with IMR roll shift(0, 100, 225 mm)Both IMR、WR benders=50 TON/2chocks, and Rolling load =500 TON.

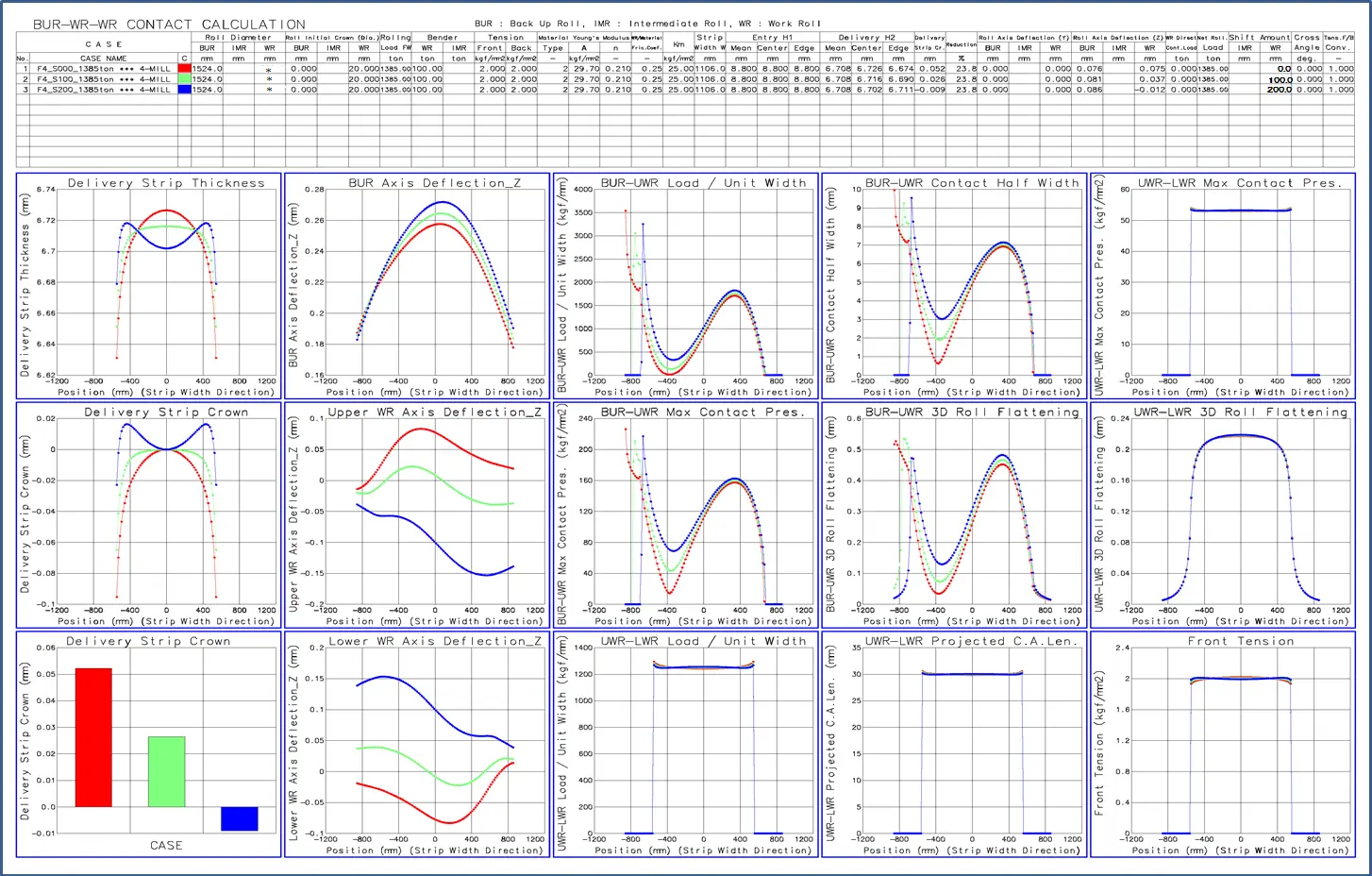

4. 4HI Mill(HOT CVC ROLL SHIFT)

FIG.6 Improvement of delivery strip crown with CVC Roll shift(WR shift amount:0 , 100 , 200 mm) Strip width:1106mm(middle width) after remodeling CVC curve

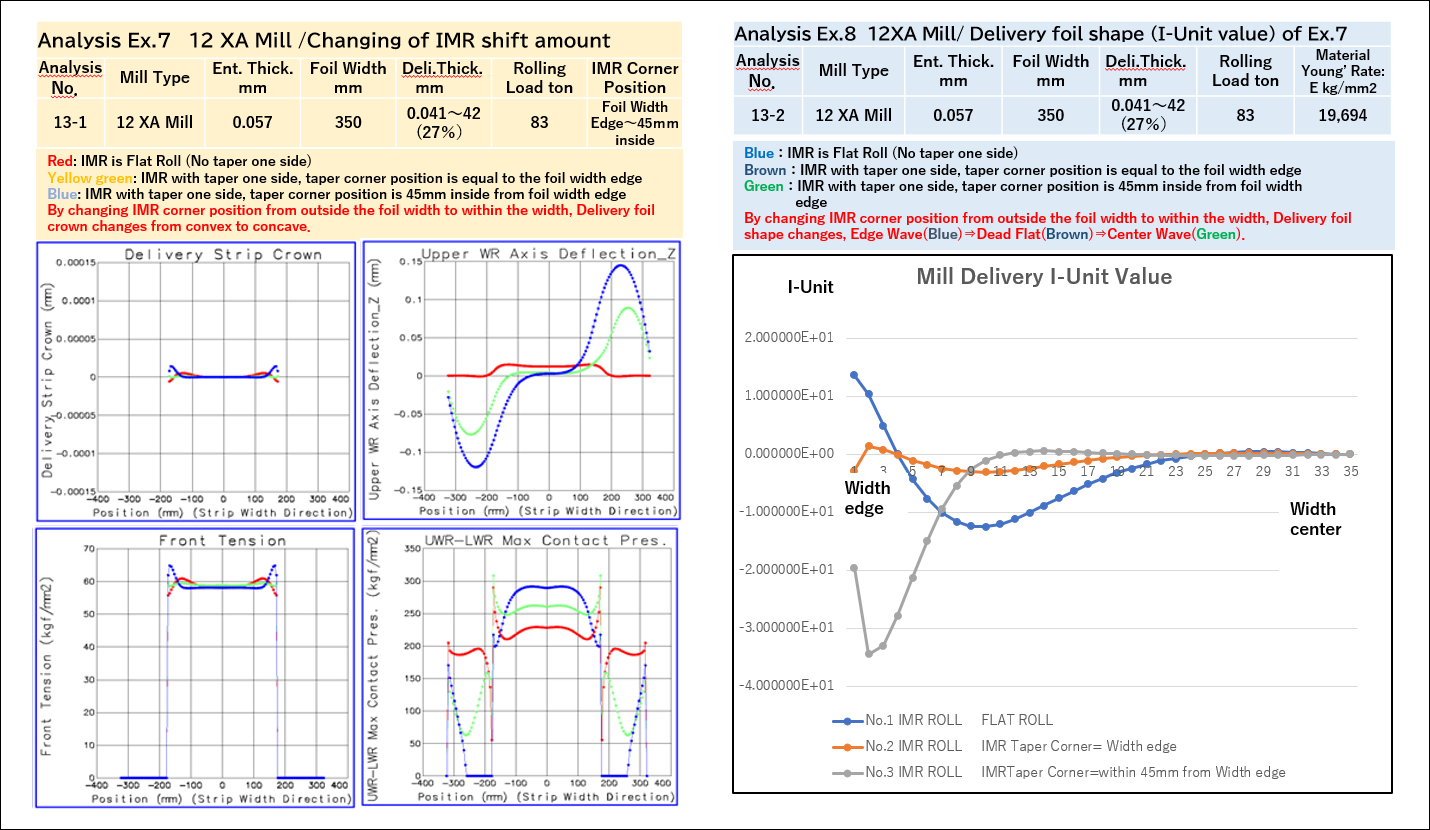

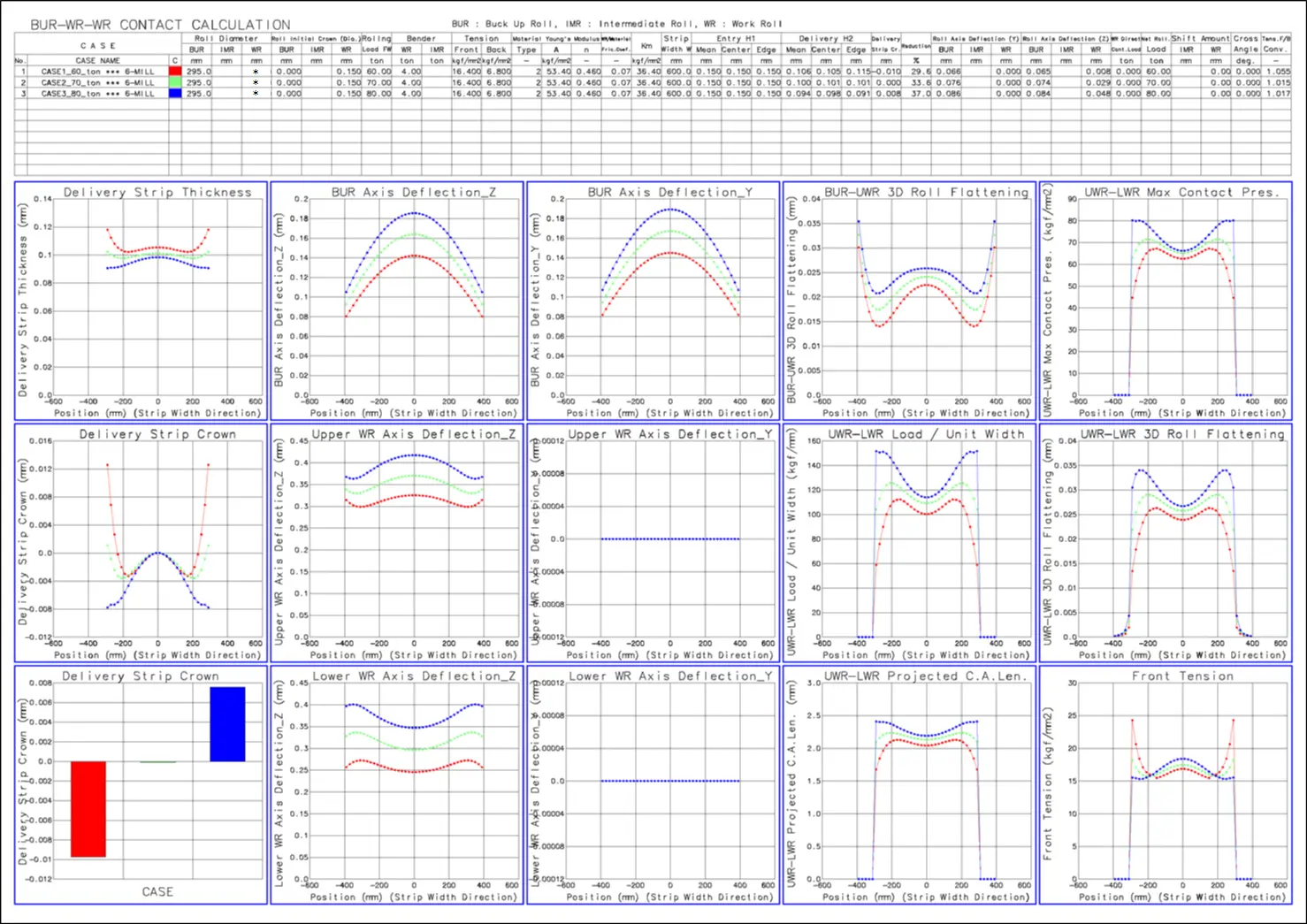

5. 6X Mill(COLD), For Copper Alloy

FIG.7 Change of delivery strip crown with Parabolic WR curve (Rolling load :60, 70, 80 TON),All WR benders : 4 TON/2chocks, WR difference : 0.15 mm

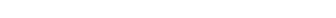

6. 10X Mill(COLD), For Copper Alloy

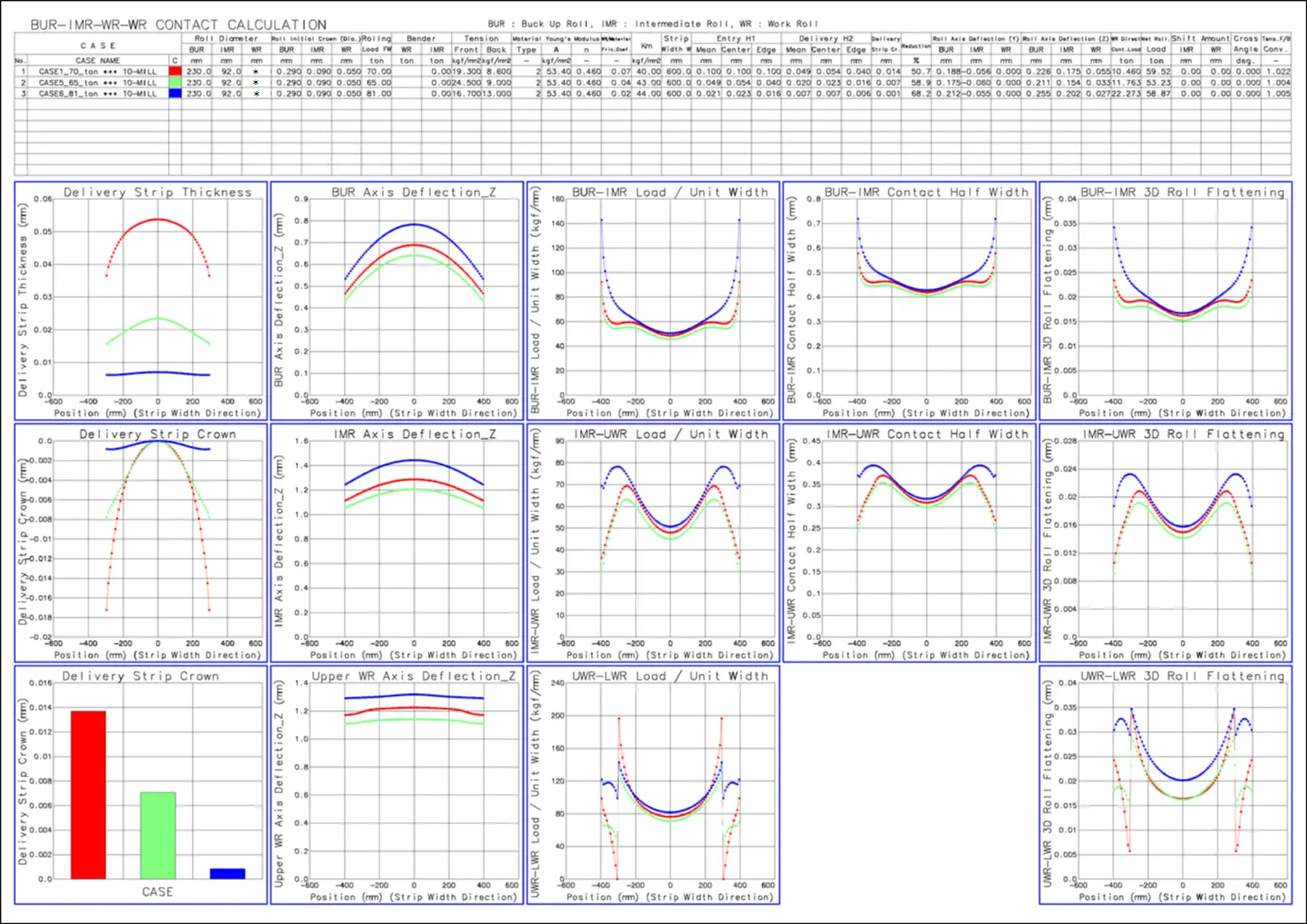

FIG.8 Study of 3 passes Foil rolling with BUR,IMR,WR crowning , Entry strip thickness 0.1 mm const.